Formwork, Mechanisation and Site Operations in Movable Scaffolding Systems

Beyond the main steel structure, the formwork system and site operations are critical to the performance and cost-effectiveness of a Movable Scaffolding System.

Internal and external formwork: configuration and mechanisation

In box-girder decks, both internal and external formwork can be integrated into Overhead or Underslung MSS. The internal formwork configuration is governed by the internal geometry of the box, not by the MSS type, so the solutions are broadly similar.

Typical characteristics:

- Normal panel length (both internal and external): 5–6 m.

- Internal formwork systems are most efficient when they are hydraulically operated:

- The system often consists of formwork panels 5–6 m long,

- A rail system, and

- A transport trolley that moves the folded internal formwork from span to span, powered hydraulically.

To ensure efficient operations, external and internal formwork panels are usually connected by threaded ties (e.g. Dywidag bars) passing through the deck webs.

Geometric conditions for using mechanised internal formwork

To make full use of mechanised internal formwork, some design decisions must be taken early in the bridge conception:

- The internal diaphragm typically located above the pier axis should be designed with a central opening of adequate size.

- This opening must allow the passage of the folded internal formwork on its transport trolley.

- Traditional diaphragms with narrow man-access openings are not compatible with fully mechanised formwork.

In theory, diaphragms can be concreted in two stages to create a larger passage opening, but:

- This usually requires extensive use of reinforcement couplers.

- The resulting cost is high and usually not competitive.

A better solution is to adjust the slab and web thicknesses near the diaphragm, allowing the diaphragm to be sized with a sufficiently large opening for the internal formwork.

Crossfall, rotation of the section and pour sequence

Deck geometry in cross-section is also important for MSS optimisation:

- Ideally, the deck cross-section should be geometrically constant, and variations in transverse slope should be obtained by rotating the whole cross-section.

- If the top slab rotates with the change in crossfall while the bottom slab remains horizontal, the web height becomes variable.

- This often forces the deck to be concreted in two stages, complicating both the formwork and the construction cycle.

Designing with MSS in mind means favouring simple, repeatable cross-sections and rotations.

Formwork surfaces: plywood vs steel

The most common formwork surface in MSS is:

- Phenolic plywood, typically 21 mm thick.

Steel formwork skins are technically possible but usually less attractive in practice:

- Rebuilding or adapting steel formwork for future projects is expensive.

- With plywood:

- The underlying steel structure is easily reused and modified for new projects.

- Plywood sheets are screwed to timber sections bolted to the steel ribs and can be replaced if the number of spans is large or the surface wears out.

For typical deck lengths and project sizes, phenolic plywood offers the best balance of cost, flexibility and finish quality.

Handling of reinforcement with Overhead MSS

Overhead Movable Scaffolding Systems are often equipped with electric winches that allow the transport of pre-assembled reinforcement cages or large reinforcement modules.

Some winch systems use toothed racks and toothed wheels, which:

- Ensure safe handling of loads on decks with longitudinal slopes.

- Reduce manual handling and increase productivity on site.

MSS as machinery under the Machinery Directive

Due to the presence of movement (launching, formwork opening/closing, internal trolley, etc.), Movable Scaffolding Systems and Formtravellers fall under the definition of machines in the Machinery Directive.

This classification implies:

- Detailed risk analyses must be carried out.

- The design must consider the risk hierarchy defined in the Directive.

- All user safety aspects (access, fall protection, emergency stops, guards, etc.) must be addressed systematically.

The result is equipment that is not only structurally safe, but also safe to operate.

Construction cycle, crew and launching speed

The typical operations when using an MSS include:

- Opening the formwork

- Launching the MSS to the next span

- Closing and adjusting the formwork (including cambering)

- Preparing for reinforcement

- Concreting and prestressing

The crew size required depends on span length, deck width and cycle time, but typically:

- An MSS requires a team of around 12–14 people to handle operations efficiently.

Regarding launching:

- A typical launching speed is about 10 m per hour.

- Higher launching speeds are technically possible, but:

- The kinetic energy of the moving MSS increases with speed.

- Any accidental contact with supports or obstacles leads to much higher impact forces.

- The small time savings from faster launching rarely justify the increased risk.

In practice, controlled, moderate speed is the standard for safe MSS operations.

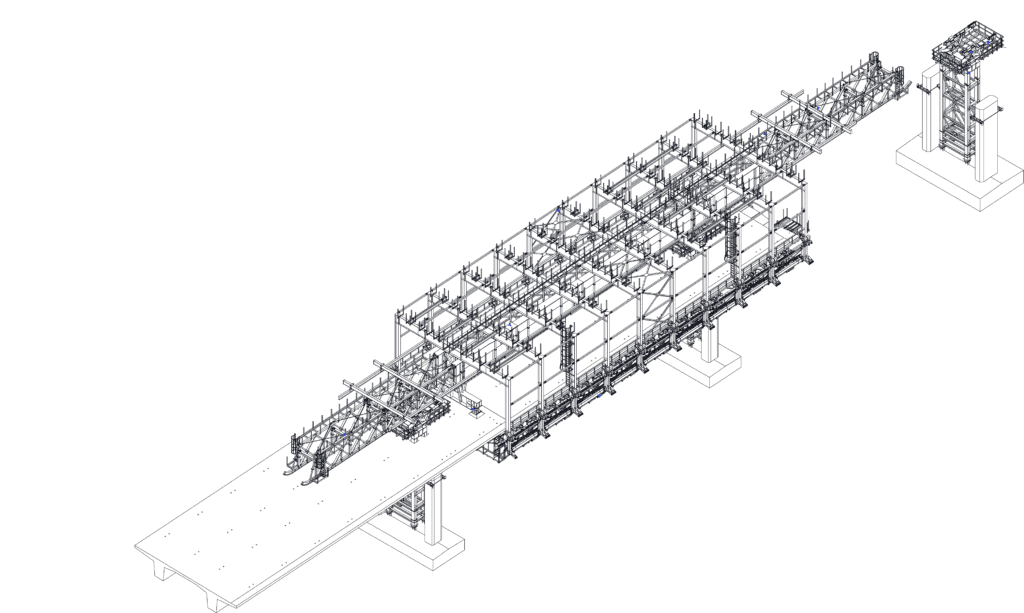

Pre-assembly, transport and bolted connections

During original manufacture:

- MSS steel structures are usually partially pre-assembled in the workshop.

- All components are marked with references to simplify correct on-site assembly.

For transport:

- Parts are typically designed to fit into 40’ containers or onto standard TIR truck platforms.

On site, proper planning of assembly and dismantling is essential:

- Correct definition of lifting points and sequences.

- Control of the centre of gravity in each assembly phase.

- Safe access for cranes and auxiliary equipment.

Bolted connections in MSS can be:

- Friction (slip-critical) connections with pre-stressed bolts, or

- Shear connections with non-pre-stressed bolts.

Each option has implications:

- Friction connections require:

- Calibrated torque wrenches,

- Strict tightening procedures,

- Non-reuse of pre-stressed bolts.

- Shear connections are usually simpler and cheaper, and are commonly adopted when design allows it.

Design Criteria Document: the key to choosing the right MSS

To evaluate whether a given MSS is suitable for a specific deck, a Design Criteria Document is essential. This document must clearly define:

- Loads from the fresh concrete

- Safety factors

- Wind speeds:

- During launching

- During concreting

- Under storm conditions

- Materials and steel grades

- Maximum span and deck weight

- Live loads and construction loads, among other parameters

The cost and site performance of an MSS depend heavily on these technical definitions. A well-prepared Design Criteria Document is the foundation for choosing or designing the right system for each project.

STRUKTURAS

WE MAKE IT SIMPLE!

Assembly of FT is done by Strukturas site team

Assembly of FT is done by Strukturas site team