STRUKTURAS tailored input with MSS and FT Construction Methods

Challenges and solutions:

- Long spans for MSS with 3 spans of 60m and first span with 48 m. lead to very optimized MSS design.

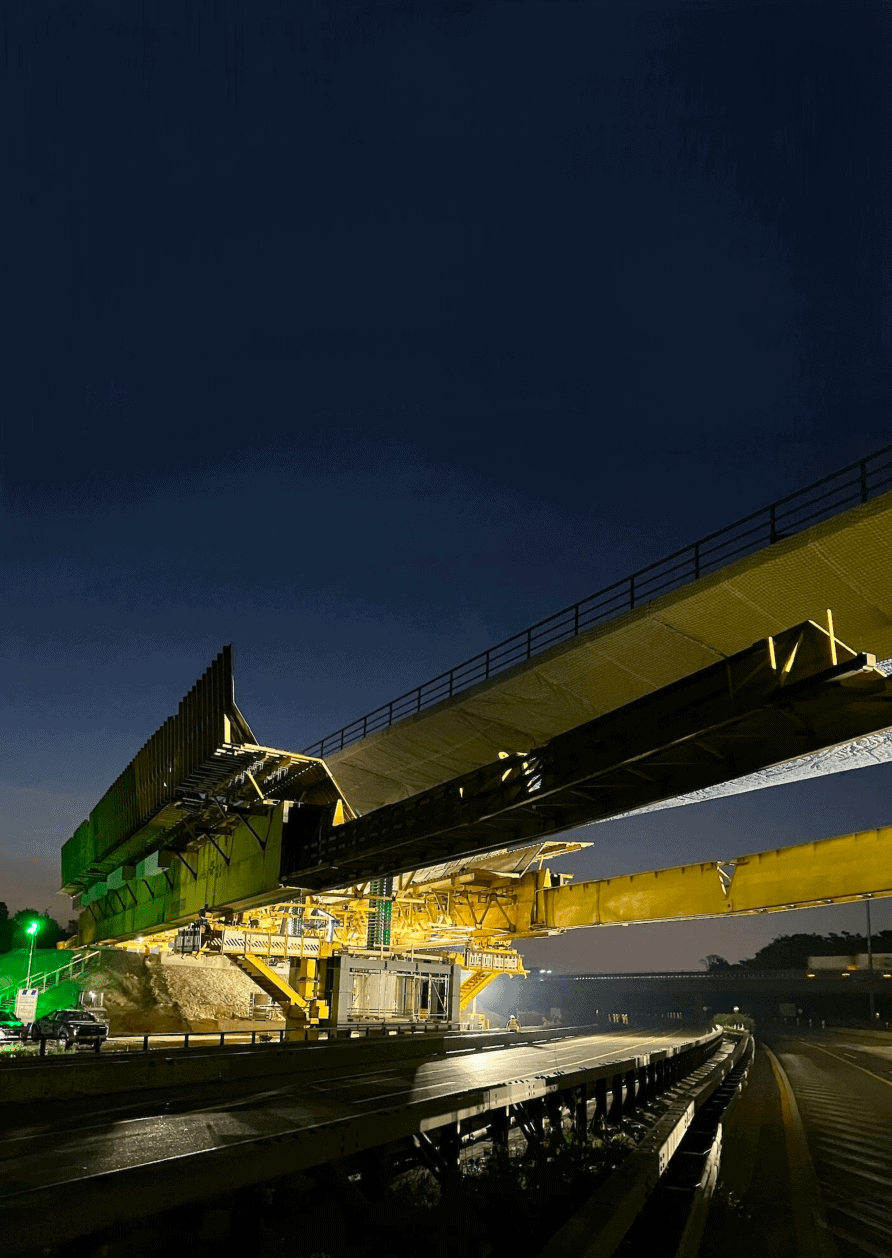

- Not much space for assembly at the first span. STRUKTURAS underslung MSS solution with assembly behind the abutment was used. MSS was launched into the first span.

- The railroad (with traffic) goes diagonally under the bridge at the second span, which makes it impossible to use a traditional scaffolding.

- The slope is big at the third and fourth spans with difficult support conditions for traditional scaffolding, nevertheless It was not the restriction for MSS.

- Pier at axis 4 is 40m high. STRUKTURAS MSS Supporting Bracket system with block outs in the piers for load transfer to piers was used.

- Small horizontal radius -1050 m. STRUKTURAS MSS includes the formwork which is made to adapt a small horizontal radius. However the launching of the MSS at small horizontal radius is possible due to rotation of the noses.

- Difficult dismantling after finishing the fourth and last concreting between axis 4/5. The costs for dismantling was kept low by lifting up the MSS on the finished deck and transport back to the abutment for transport.

Outcome:

Revolutionizing Construction: STRUKTURAS spearheaded the transformation of construction methods by introducing advanced MSS and FT technologies. It allowed for a dramatic reduction in labor while maximizing the utilization of machinery.

Maximizing Efficiency: STRUKTURAS delivered 2 pairs of FT and 1 Underslung MSS for 60m spans inclusive assembly, operation and dismantling of the MSS.

Precise Execution: STRUKTURAS involvement ensured precise execution at every stage of construction.

Safety and Quality: STRUKTURAS prioritized safety and quality throughout the planning phase. Their input led to the development of construction methods that not only accelerated the project but also enhanced safety standards and overall quality.

Aquilino Raimundo, construction methods expert at Strukturas as, comments as follows: “The collaborative partnership between the designers, contractor and STRUKTURAS, with a significant focus on advancing MSS and FT construction methods showcased how early contractor involvement can lead to visionary designs that are not only aesthetically pleasing but, as a matter of fact, also constructible, efficient, and innovative in construction.”

STRUKTURAS Integrated Services On-Site

From Supervision to Cambering. STRUKTURAS involvement extended beyond equipment supply. They offered integrated services on-site, ensuring that every aspect of construction was executed with precision. From supervision and mobilization to assembly, launching, and cambering, STRUKTURAS played a vital role in every stage of construction.

Øyvind Karlsen , comments: “The sum of the complex factors from the geometry of the Randselva bridge made the MSS technology from STRUKTURAS perfect. Our integrated services were crucial in ensuring that the project proceeded smoothly”.

Conclusion

The Randselva Bridge stands as a remarkable testament to what can be achieved with visionary design, cutting-edge technology, and global collaboration converge. With a focus on innovative construction methods, the bridge industry is transitioning towards mechanized construction, enhancing efficiency, safety, and quality.

As we look to the future, the lessons from the Randselva Bridge project inspire us to push the boundaries of engineering and redefine what’s possible in bridge construction. It’s a reminder that the future of engineering is not bound by paper but driven by innovation and collaboration.

Global collaboration and early contractor involvement played a key role in its success.

Randselva was the 20th bridge built in a cooperation between Strukturas as and ARMANDO RITO ENGENHARIA, SA . Our cooperation lasts more than 25 years:

1. E16 Eggemoen – Åsbygda, Norway | Randselva brigde 2019

2. IC5 – Murça (IP4) / Nó de Pombal, Portugal | Tua bridge 2010

3. A32/IC2 – Oliveira de Azeméis / IP1 (S. Lourenço), Portugal | Canedo viaduct 2010

4. A32/IC2 – Oliveira de Azeméis / IP1 (S. Lourenço), Portugal | Ínsua I bridge 2010

5. Estrada Catete/Muxima – Província do Bengo, Angola | Kwanza II bridge 2009

6. Estrada Catete/Muxima – Província do Bengo, Angola | Kwanza bridge 2008

7. A32/IC2 – Oliveira de Azeméis / IP1 (S. Lourenço), Portugal | Uima II bridge 2008

8. A41 – Picoto (IC2) / Nó da Ermida (IC25), Portugal | Uima I bridge 2008

9. A17 – Auto-Estrada Marinha Grande / Mira, Portugal | Mondego bridge 2008

10. Express motorway Benguela / Lobito – Província de Benguela, Angola | Catumbela bridge 2007

11. A17 – Auto-Estrada Marinha Grande / Mira, Portugal | Mondego bridge 2006

12. IP3 – Scut Interior Norte, Portugal | Vila Pouca de Aguiar viaduct 2006

13. Viaduct Rib Alcobertas, Portugal 2006

14. A11/IP9 Braga-Guimarães – IP4/A4, Portugal | Vizela viaduct 2005

15. A10 – Auto-Estrada Bucelas / Carregado, Portugal 2004

16. A11/IP9 Braga-Guimarães – IP4/A4, Portugal | Vizela viaduct 2004

17. A7 / IC5 Guimarães-Fafe, Portugal | Nepereira viaduct 2003

18. A25 / IP5 Mangualde – Guarda, Portugal | V1 and V2 viaducts2003

19. EN125 Portimão, Portugal | Arade bridge 2001

20. A2 Southern motorway, Alcácer do Sal Portugal | Sado viaduct 1998