Structural Design, Geometry and Safety of Formtraveller

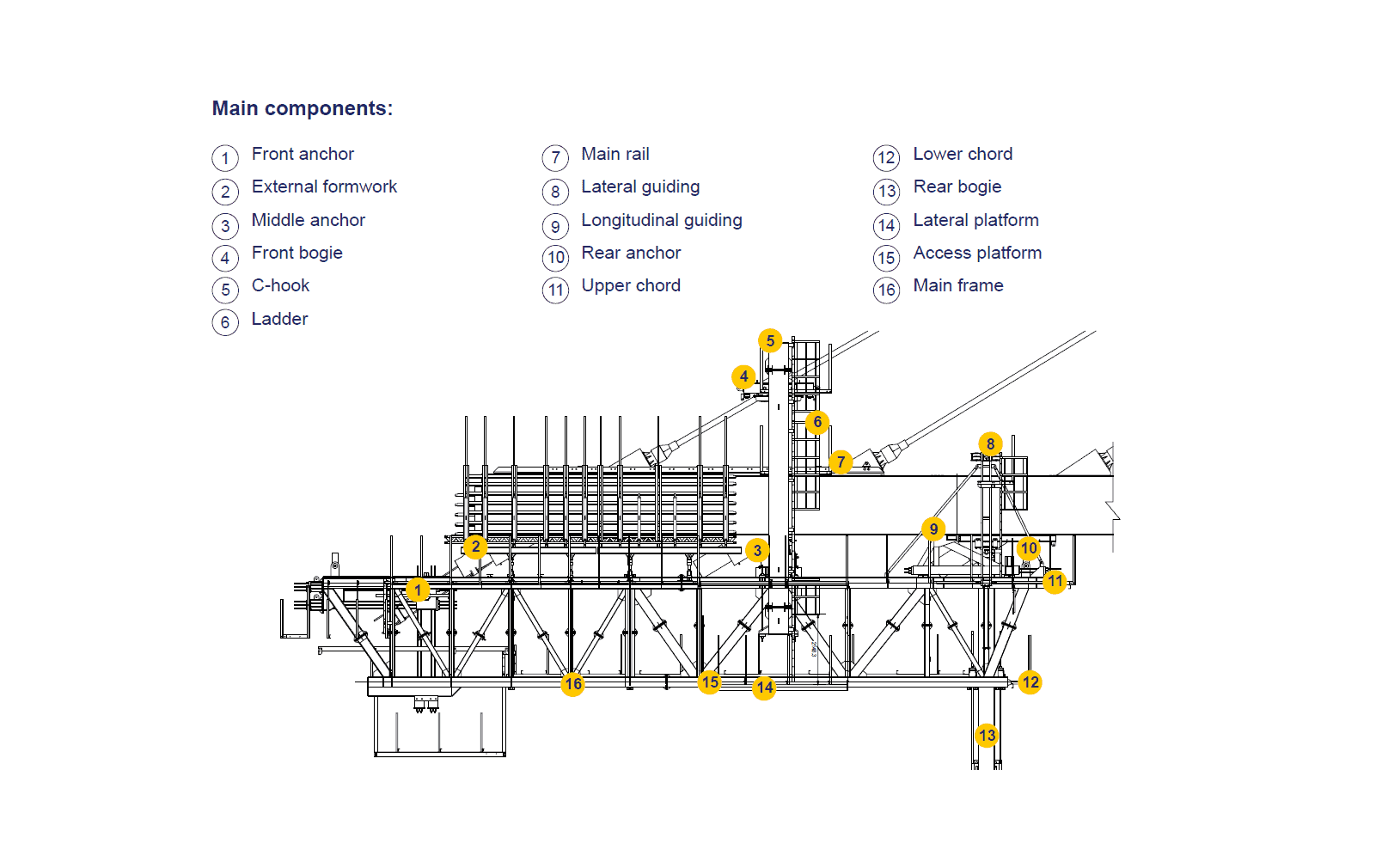

Formtraveller are complex steel structures that support fresh concrete, reinforcement, construction live loads and self-weight during both casting and launching stages. Their structural design must comply with strict criteria for deformation, safety and geometric compatibility with the bridge deck.

Deformation limits and design codes

During the design stage, maximum deformability is carefully controlled:

- For the main structure of the Formtraveller, a maximum global deformation of L/400 is normally considered, where L is the span of the main structure.

- For local elements, such as individual formwork profiles, the usual limit is L/250 for the span of the profile in question.

These limits ensure proper deck geometry, correct camber and acceptable stress distributions in both the temporary equipment and the permanent structure.

Regarding design standards:

- Eurocode is typically used for the assessment of structural safety.

- EN 1090 is used for quality control of the fabrication of the steel structure.

Connections, anchorage and checks on the permanent structure

Formtravellers are connected to the concrete deck using anchors made of threaded bars, which pass through blockouts in the bottom and top slabs. These anchors transmit:

- Vertical loads

- Stability-related forces during both casting and launching

Before casting a segment, it is essential that the reactions from the Formtraveller (in both casting and launching configurations) are submitted to the bridge designer. The designer must:

- Verify the columns and

- Check the deck section

for all relevant construction-stage load combinations.

These checks are critical, since cantilever construction can produce more severe stresses in some sections during construction than in the final service condition.

Geometric conditions: diaphragms, web spacing and internal formwork

The geometric conception of the deck has a strong influence on the practicality of using Formtraveller, particularly when internal formwork is present.

Key aspects include:

- Position of diaphragms

- To allow mechanised internal formwork to be launched from segment to segment, the internal diaphragm should be placed at the rear of the segment. Same is applied to the external diaphragms and external formwork.

- If diaphragms are located near the front of the segment, the internal formwork behind them cannot be launched forward and must be dismantled or lowered, which is inefficient and time-consuming.

- Concreting diaphragms in two stages to create a passage for the internal formwork may be possible in some cases, but this is a decision for the bridge designer and may complicate reinforcement arrangement.

- To allow mechanised internal formwork to be launched from segment to segment, the internal diaphragm should be placed at the rear of the segment. Same is applied to the external diaphragms and external formwork.

- Distance between deck webs

- For optimal use of Formtraveller formwork, it is very important that the distance between the deck webs remains constant along the deck.

- Constant web spacing facilitates repetitive, standardised internal and external formwork and simplifies tie arrangements.

- For optimal use of Formtraveller formwork, it is very important that the distance between the deck webs remains constant along the deck.

Longitudinal slope and launching safety

From a theoretical point of view, there is no absolute limit on longitudinal slope for decks built with Formtraveller Systems. However:

- When the deck longitudinal slope is large, some modifications are needed:

- The Formtraveller must be able to stay horizontal during casting, to ensure correct concrete distribution and work conditions.

- During launching, the system must be able to follow the deck slope.

- The Formtraveller must be able to stay horizontal during casting, to ensure correct concrete distribution and work conditions.

- A braking device must be included, ensuring that the Formtraveller remains safely in position on top of the rails during launching, especially on significant slopes.

The hydraulic cylinders used for longitudinal launching typically include a safety valve:

- In the event of a hydraulic pipe rupture, this valve blocks the oil inside the cylinder.

- This instantly stops the movement and prevents uncontrolled displacement of the Formtraveller.

Classification under the Machinery Directive

Because Formtraveller involve movement (launching, formwork opening/closing, internal formwork repositioning), they fall under the definition of machinery in the Machinery Directive.

This classification requires:

- Detailed risk analyses, covering all operating modes.

- Application of the risk reduction hierarchy defined in the Directive.

- Design solutions that address user safety in a systematic way (access, fall protection, guarding, emergency stopping, etc.).

In practice, a compliant Formtraveller is not only structurally sound, but also engineered as a machine with safety-integrated design.

STRUKTURAS

WE MAKE IT SIMPLE!

If you have any questions or would like to discuss the possibilities for your bridge project, please get in touch with your local agent or our head office in Norway: CONTACTS